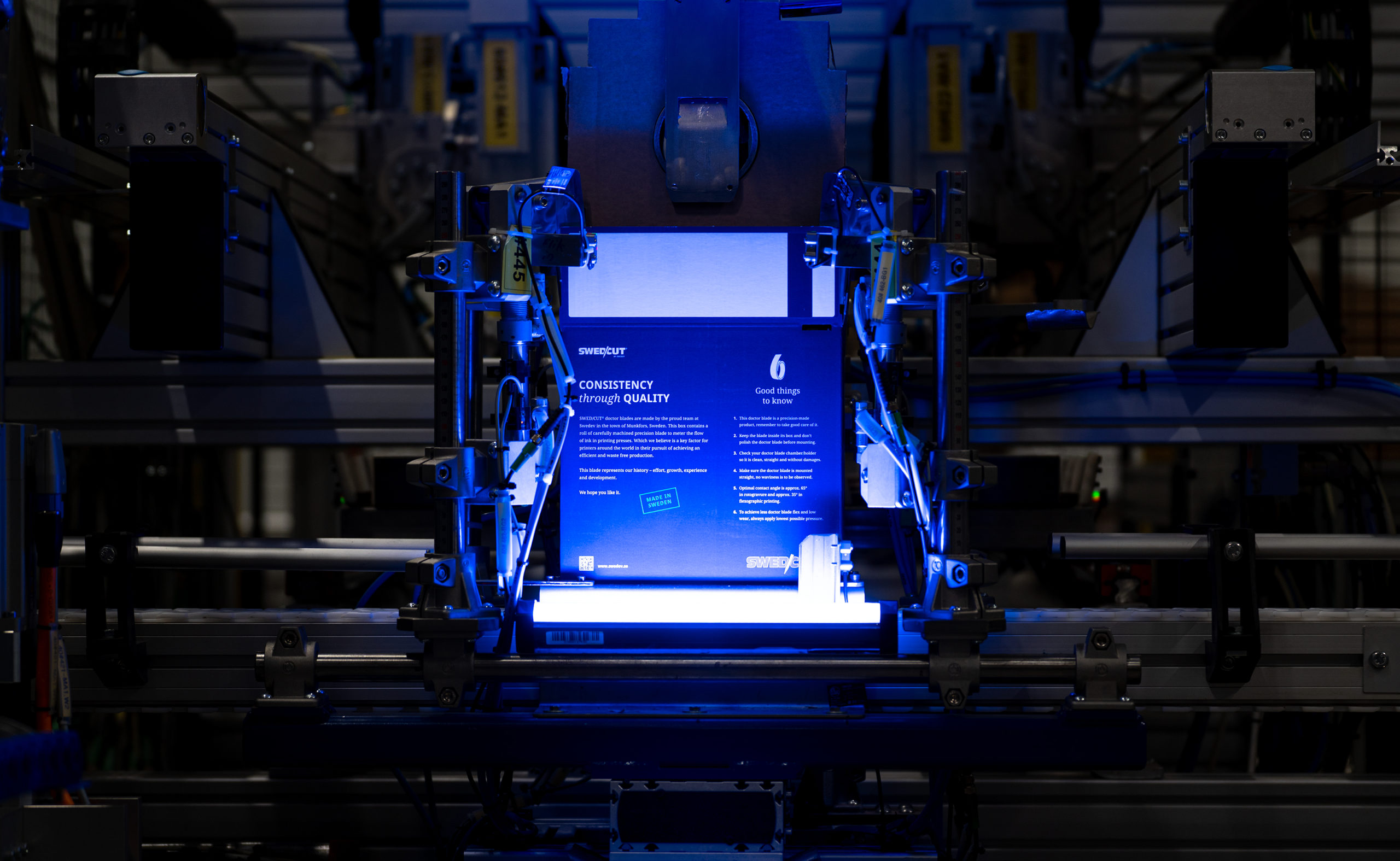

M-Flex Plus

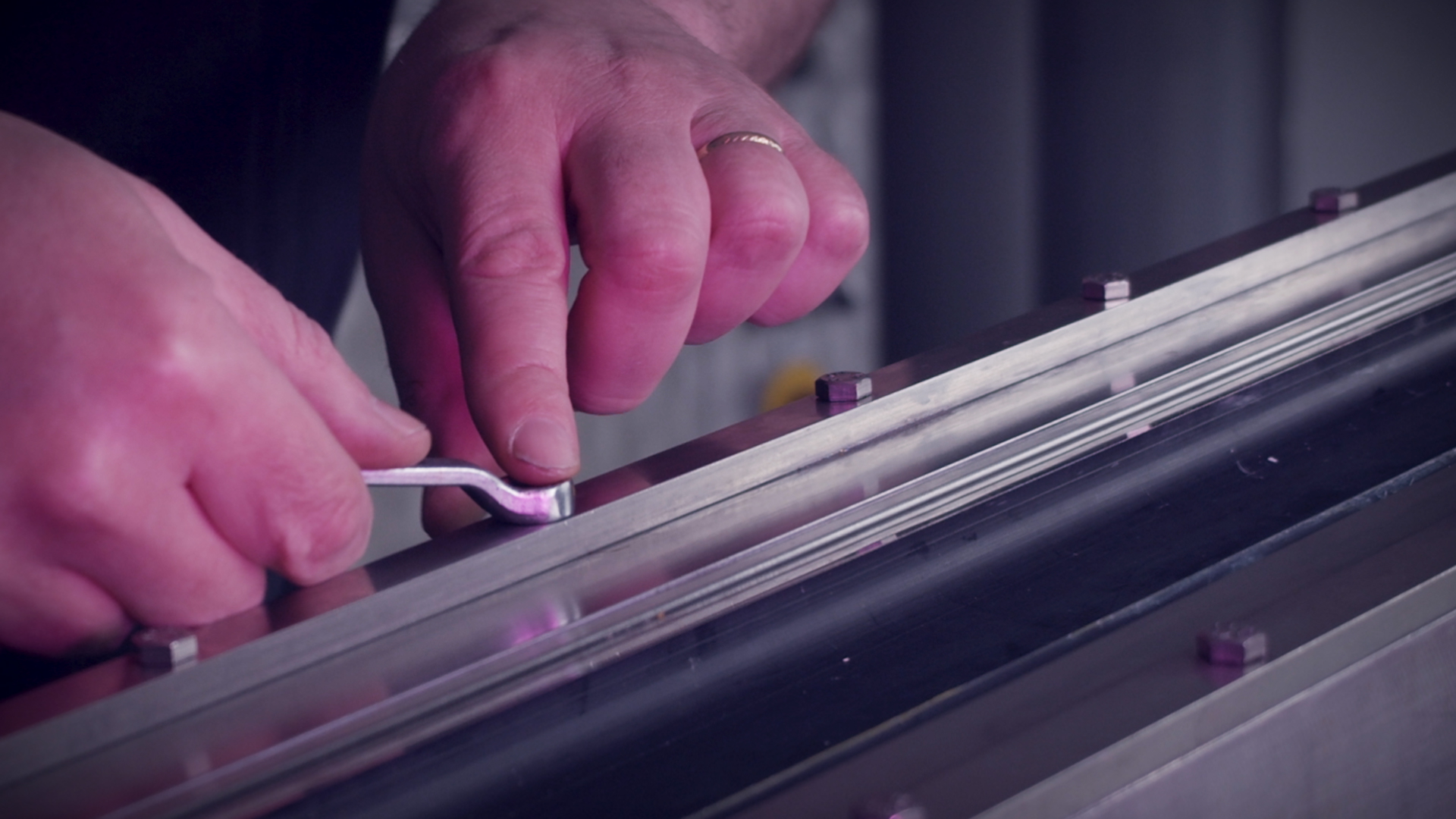

M-Flex Plus doctor blade for flexo printing is our most resistant steel printing doctor blade. M-Flex Plus is made of remelted steel, ESR (ElectroSlag Remelting) steel. ESR is a process of remelting and refining steel.

This kind of steel is often used when quality is critical since it is a very clean steel with more uniform composition than conventional steels. M-Flex Plus doctor blade is a superb solution for all flexo printing when using abrasive ink and its hardness delivers up to 25% higher wear resistance than other quality tool steel.