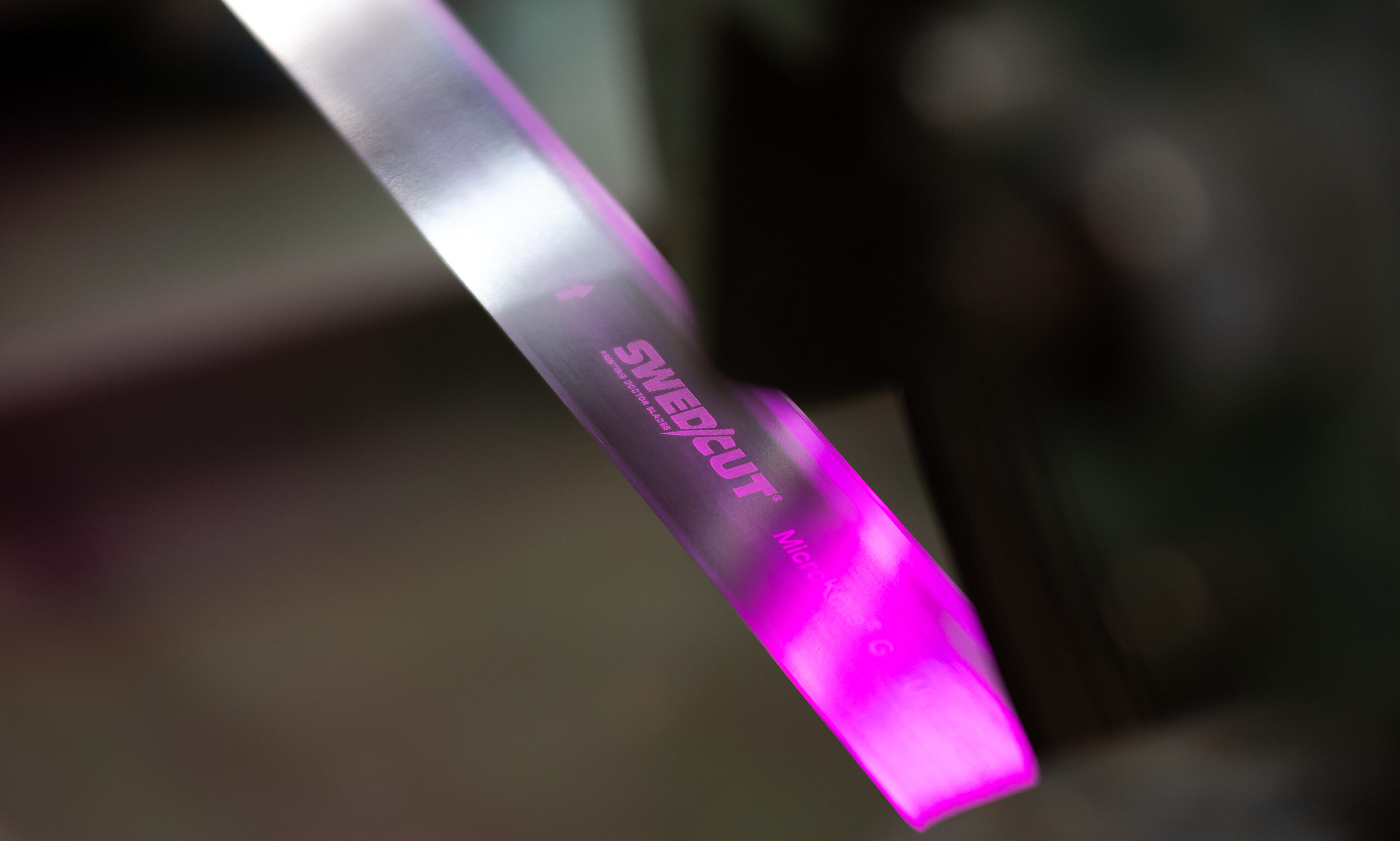

H9

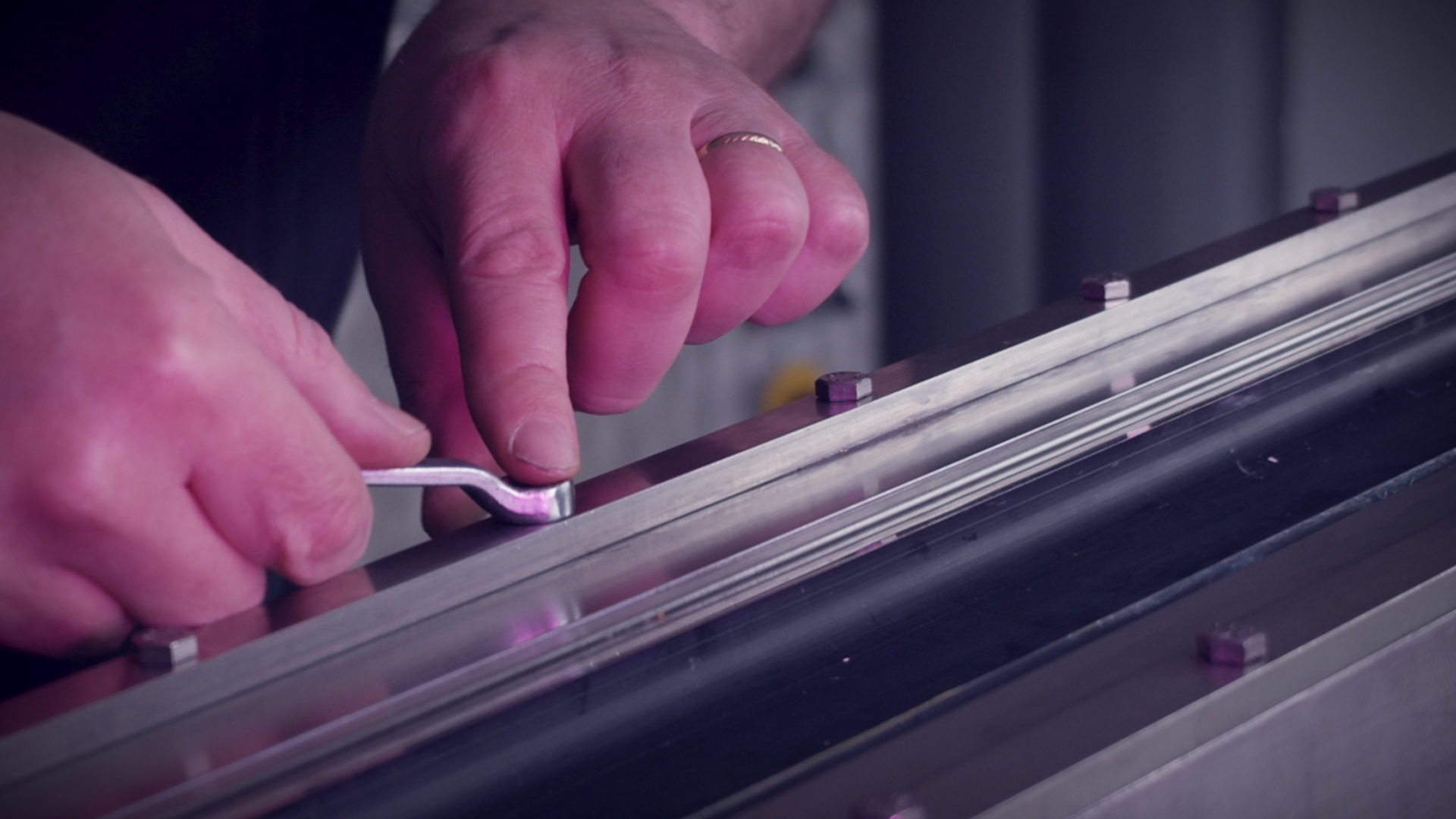

Swedcut® H9 doctor blade is developed for flexo printing to reduce downtime and improve productivity. The Swedcut® H9 is an excellent choice when printing conditions require a harder blade. Swedcut® H9 is a perfect printing doctor blade in when white/abrasive inks and lacquers are used.